Part 1 Introduction

Wood boilers can be an environment friendly option for home heating. Some of them had evolved and use “gasification” to burn wood with high efficiency and at the same time, because of the high temperature of the flame also particulate emissions. This is very important when burning wood.

Efficient burning regulation can be obtained by applying modern electronic control, i.e. by using lambda sensors to adjust the comburent air and thermocouples to measure temperature.

Unfortunately some years ago this was not so common to find, and wood boiler controllers were not so evolved. So how to give a better and more comfortable control and user experience? And how to monitor remotely a all important parameters? For example, I would like to know when wood has finished to burn without going to basement 10 times a day ! 🙂

In section picture above you see typical internal disposition. Fire area is depressurized by a ventilator fan. Fresh air goes through wood, reach burning area, burns; hot gases cross heat exchanger giving heat to water. Finally combusted gases cross fan to chimney.

Wood boilers are not stand alone components, but need a lot of additional components to deliver heat in the proper way. Most import is the pairing with a proper water puffer, that is an additional heat storage which ensures the continuity of house heating when there is no fire. By this way you cover all day heating needs with one ignition a day.

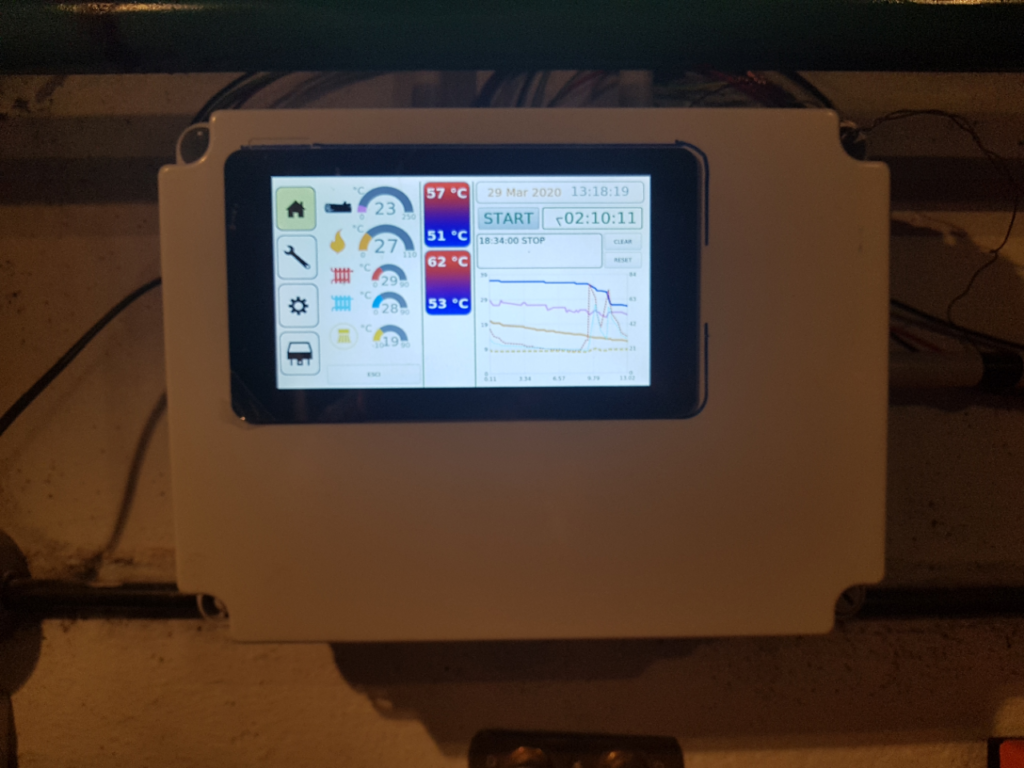

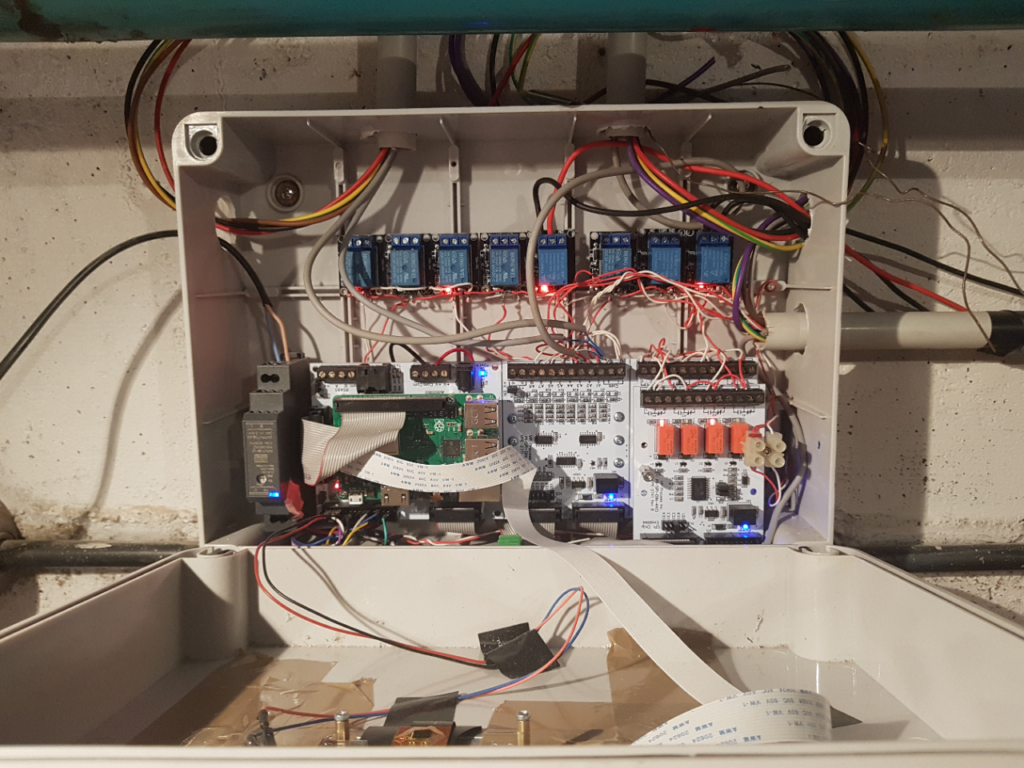

Well…there is a lot to tell here 🙂 I will just show the main panel here and in the next posts I will try to explain all the parts of the project. Stay Tuned !

Hello I know this web site presents quality based content and extra information, is there any other web page which presents these data in quality? many thanks

Hi, in future I will add some more details. What do you need in particular ?